Industrial X-Ray based Inspection Machines (CT, Cabinet Type & Micro Focus)

Industrial X-ray-based inspection machines refer to specialized equipment used for non-destructive testing and inspection in various industries. There are several types of industrial X-ray machines, including CT (Computed Tomography), Cabinet Type, and Micro Focus systems. Here is an overview of each type and their uses:

1. Computed Tomography (CT) Systems:

CT X-ray machines use a rotating gantry to capture multiple X-ray images from different angles. These images are then reconstructed to create a 3D model or cross-sectional slices of the object being inspected. CT systems are commonly used for:

- Industrial Metrology: CT can provide precise dimensional measurements, internal structure analysis, and surface reconstructions for quality control purposes.

- Failure Analysis: CT is useful for identifying internal defects or failures in components or assemblies without damaging them.

- Reverse Engineering: The 3D scanning capabilities of CT allow the creation of digital models from physical objects, aiding in product development and design.

2. Cabinet Type X-ray Systems:

These systems consist of a lead-shielded cabinet with an X-ray tube and a detector panel inside. The object to be inspected is placed on the cabinet’s conveyor system or platform, and the X-rays pass through it to create an image that can be viewed on a monitor outside the cabinet. Cabinet type X-ray systems are commonly used in various industries for:

- Quality Control: These systems can detect defects, voids, cracks, or foreign objects in manufactured components or assembled products.

- Component Analysis: Cabinet type X-ray systems are used to inspect the internal structure and integrity of electronic components, such as IC chips, connectors, and PCBs.

- Security Screening: These machines can be utilized for screening packages or bags in high-security environments to detect any hidden threats or contraband items.

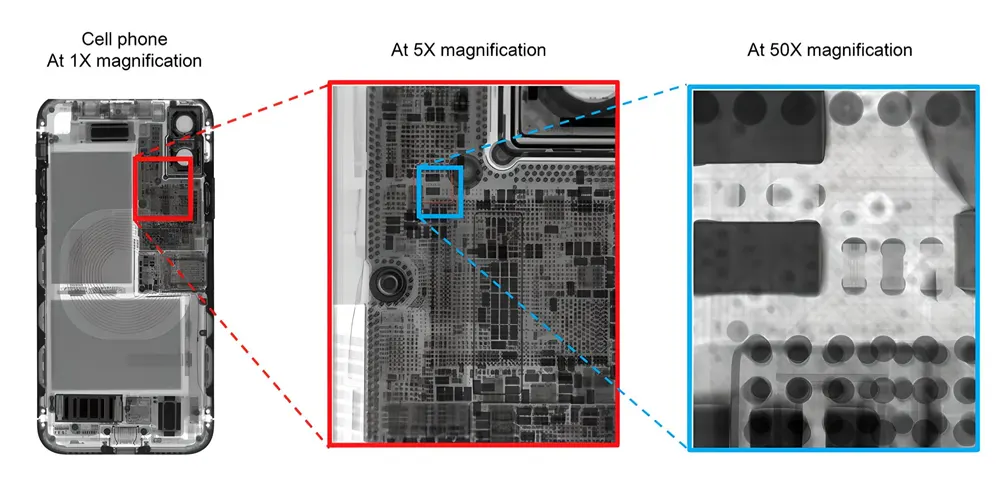

3. Micro Focus X-ray Systems:

Micro Focus X-ray machines use a small focal spot size X-ray source to produce highly detailed images with high resolution. These systems are often used for:

- Electronics Inspection: Micro Focus X-ray systems can identify defects in solder joints, wire bonds, and other microelectronic components with very high precision.

- Semiconductor Industry: These machines are used to inspect integrated circuits (ICs), wafer-level packages (WLPs), semiconductor devices, and other microscale components.

- Medical Device Manufacturing: Micro Focus X-ray inspection is utilized to ensure the quality and reliability of medical devices such as pacemakers, stents, or implants by detecting any manufacturing defects or flaws.

We’d like to hear from you!

Still need help or have any query?

Please fill the form and we will guide you to the best solution. Our experts will get in touch soon.

Call Us

Call Us Whatsapp

Whatsapp Mail Us

Mail Us